The ever-increasing demands of manufacturing processes generate excessive wear of tools and tooling and make necessary the appearance of means to slow down such deterioration while maintaining the operation at a high level of efficiency. In response to this problem, coatings have emerged, capable of delaying, among other things, abrasive, thermal or chemical wear, as well as achieving higher quality in their operations and improving process conditions.

In particular, a PVD coating is a thin ceramic layer of a few microns thick, with exceptional hardness, which is deposited on substrates in order to provide properties that make up for the deficiencies of the substrate, whether functional or decorative properties. The roughness is low as long as the substrate also has a good finish. It is around 0.04 Ra- 0.15 Ra, and can be lower in exceptional cases.

The properties provided by the coating depend at all times on the type of coating deposited, in terms of structure, material or thickness, as well as the treatments applied to the surface before and after coating. Both the treatments and the type of coating must be chosen according to the results of a rigorous examination of the application to which the substrates are destined, therefore the characteristics provided will not generally be the same.

In general, the properties that can be improved are the following: Mechanical, physical, tribological, chemical, electrical, optical and/or biological.

It is important to know that the coating has a multiplicative effect, i.e. it improves the performance of the tool, but if the tool is not in good condition, its contribution will be limited.

Coatings have many applications both by operation and by sector. By operation, the main groups are cutting tools, deformation tools, injection and components. While by sectors we could mention the railway, automotive, aerospace, biomedical, construction… Coatings do not have a closed field of applications, since there are diverse environments in which they can provide benefits.

Although there are many characteristics that can be controlled in a PVD coating, the following are the most common and important:

Thickness. The ideal value of this parameter again depends on the intended application of the substrate. In micro tooling, the deposition of large layers can lead to a loss of tolerance in the operation, while in stamping, a high layer thickness is of interest.

Adherence. A failure of this property is likely to nullify the positive effect of the coating. In general, adhesion coatings and surface treatments are applied to increase the guarantee against this type of failure.

Thermal stability. In operations where heat generation is high, it is necessary to ensure the preservation of coating properties at high temperatures and to avoid premature degradation of the coating.

Chemical stability. For processes where the tool material may interact with the work material is a factor to be controlled, thus avoiding adhesion phenomena of the work material to the tool. Application against oxygen, chemical media, molten metals, etc.

Roughness. Closely related to the coefficient of friction and therefore to abrasive wear. In cutting tools it is generally of interest that it is low, while in other cases, a certain roughness is necessary.

Thermal insulation. In general, it should be high to prevent the heat from being absorbed by the substrate material, especially operations where high temperatures are used.

Hardness. Closely related to abrasive wear but in general also related to brittleness. Again, the ideal value must be sought for each operation.

Resistance to oxidation and corrosion. Important to avoid deterioration of the tool in aggressive environments or at high temperatures.

Residual stresses. To avoid surface fatigue suffered by the coating in the presence of discontinuous loads. A certain level of compressive stresses is interesting, but an excessive value may limit the admissible thickness.

PVD stands for Physical Vapour Deposition, or physical vapor deposition. MEX coatings are carried out by this process, which is the most successful according to the growing market share and innovations introduced in the last 20 years. During the process, the targets are heated through an electric arc guided by a magnetic field. The temperature is raised to such an extent that part of the solid cathode particles sublimate, evaporating in the vacuum chamber. These highly ionized particles are directed to the substrates by the application of a potential between targets (cathode) and substrates (anodes) through a vacuum plasma and reacting with the gas present in the chamber, until the desired composition is achieved.

Throughout the process, a maximum temperature of around 500º C is reached, therefore it is highly recommended that all substrates to be coated have undergone a previous heat treatment at a temperature above 500 ºC and stress relaxation.

A COATING FOR EVERY APPLICATION

It is important to use the most suitable coating for each application, so it is important to follow the advice of a technical person who has an in-depth knowledge of the coatings and their properties, as well as the operation for which they are intended.

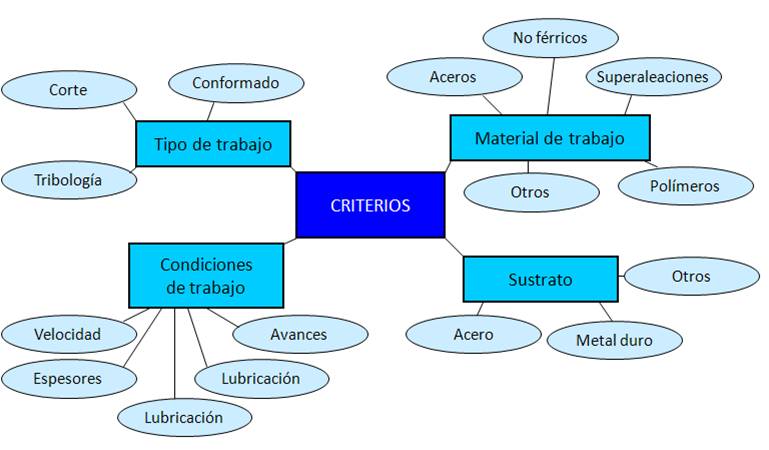

To give an accurate recommendation it is necessary to know as much information as possible about the way the coating works. The fundamental characteristics are the type and material of the tool, the type of operation, the material to be worked, the type of lubrication and special conditions if any (high speed, high start-up rate, high temperatures…). Although it is also convenient to know the type of wear suffered by the bare tool and the life criteria of the tool.

One option offered by Metal Estalki through access to prestigious laboratories, is the analysis of the tools used to know the causes of failure and study the possibility of improvement.

INFLUENCE OF THE CONDITION OF THE TOOLS BEFORE COATING

Another aspect that conditions the good performance of the coatings is the condition of the tools before coating. Metal Estalki recommends the following:

PICKLING AND LAYER BUILD-UP

The accumulation of too many coatings after successive regrinds can cause spalling that is detrimental to the performance of the tool, so it is necessary to perform an analysis of the tool to determine the need for stripping previous coatings.

PRE- AND POST-TREATMENT OPERATIONS

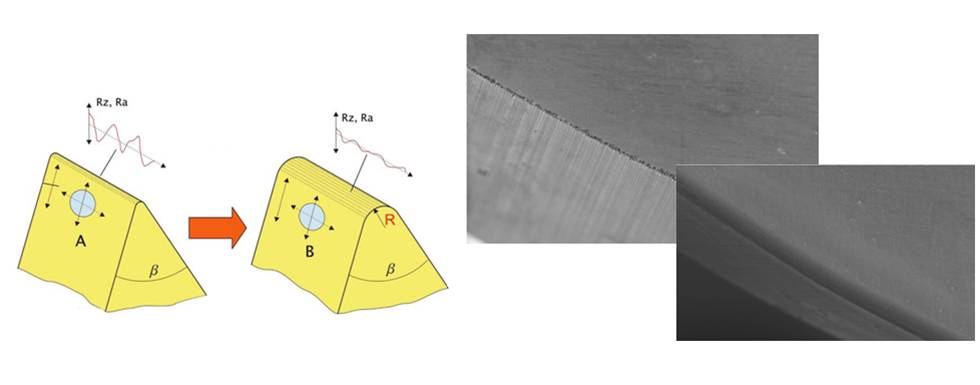

To optimize the use of the coating, it is advisable to prepare cutting edges. Each tool has an optimum radius and surface roughness for coating. It is recommended to consult a technical person about the necessity of pre- and/or post-treatment of the surfaces.

LIMITATIONS OF THE PVD COATING PROCESS

PVD coating, like all processes, also has its restrictions and these are as follows:

The only condition for coating a substrate is that the temperature of the last heat treatment undergone by the substrate is higher than the process temperature, which in no case is higher than 500 ºC. Prior stress relaxation is recommended, although in general distortions are negligible. It is feasible to coat most tool steels, but they must have been tempered to at least 500 ºC (preferably to 550 ºC in three temperings). All high-speed steels, hot work steels and powder metallurgy steels can be coated, as well as nitriding steels and hard metals. Most steels for plastic molds are suitable, and all are suitable for CrN, whose cycle temperature is lower. Stainless steels, although some require special processes, most can be coated at traditional temperatures. On the other hand, some case hardening and cold working steels present problems when it comes to coating, and in the case of non-standard materials, it is advisable to ask before coating.

Other considerations must be taken into account when dealing with hard metal brazed plate steel tools. The welding material must have a melting point above 600 ºC, and be free of Zn and Cd, due to the risk of severe contamination of the working areas. The same applies to cracks, which besides being undesirable for mechanical reasons, are areas of accumulation of contaminants and therefore act to the detriment of adhesion. In addition, a stress relaxation process is advisable before coating.

For optimum coating of substrates, minimal surface conditioning is required to adapt them to the requirements of PVD deposition, which can be summarized as follows:

Treatments or agents that affect the surface composition and that can be removed without altering the surface quality. It is advisable to remove them before sending them to the coating center.

Treatments or agents that affect the composition of the surface and that cannot be removed without altering the surface quality.

Care must be taken on ground surfaces:

More possibilities for the future

CVD coatings have been used industrially in the tooling industry since the 1960s. There were few developments until the 1990s, when the types of coatings offered stagnated and very few developments have occurred since then. Today, few coating centers offer more advanced products than TiN and TiC.

PVD coatings made their appearance in the 80’s of the last century and their evolution has been tremendously fast producing a huge variety of compositions to give specific solutions to the different needs of the industry. A PVD coating center with Platit technology is able to offer with a single PVD equipment more than 15 different types of coatings without having to make configuration changes in the equipment.

On the other hand, the development of new PVD coatings is the order of the day, being able to offer customized solutions to different customers in a way that would be unthinkable by means of CVD coatings. Metal Estalki has small-sized PVD coating equipment capable of offering specific solutions to small toolmakers.

Extended properties

The hardness ranges of PVD coatings can reach up to 45 GPa (approx. 4500 Vickers) with hot hardness far superior to CVD coatings, thanks to the nanometric structures applied to the latest PLATIT technology PVD coatings. CVD coatings barely reach 40 Gpa.

Excellent adhesion level on hard metal for PVD coatings. Absolute compatibility on all grades of hard metals. Although the first layer of PVD coatings has a higher adhesion because it is thermal, in CVD there is the problem of adverse reactions with hard metals in some grades creating fragile compounds.

Possibility to pickle both hard metals and coated steels and restore the surface of the tools to their pre-coating conditions without significant increase in roughness. Something impossible in CVD processes due to the existence of a diffusion zone. This allows not only the recovery of used tools for further use but also a guarantee of product quality because non-conforming coating processes can be recycled in a simple way and produce a coating with the required quality.

PVD coatings offer the possibility to produce mixed coatings with a hard and an anti-adhesive layer on top of it, for work materials that tend to stick together, structures that are not possible to produce by CVD.

Process

In PVD coatings, the process is carried out at temperatures below 500 ºC, being totally respectful of the vast majority of tool steels as well as all grades of hard metals. However, the high process temperatures of CVD (1000 ºC) cause edge rounding in hard metal and deformations in the steel that make subsequent heat treatments necessary.

PVD coatings provide the ability to select the surfaces to be coated by masking in a very simple and economical way. As they are based on a physical deposition technique, all exposed surfaces are coated while the non-exposed ones are not coated. Such surface selection is not possible in CVD coatings because they are based on gas reaction processes.

Quality for the most demanding customers

Thickness more controlled and reproducible. Selectable, depending on the coating, from 0.5 microns to 14 microns. In CVD, large thicknesses can be formed in a less controlled manner.

Respect of customer tool tolerances. Controlled thickness allows the production of more precise tools, which is increasingly required in the industry.

In cutting punches, it is possible to coat cutting edges with cutting edge radii of less than 5 microns, allowing the preservation of an extremely sharp cutting edge radius, which is not possible with CVD due to the extreme rounding produced by these coatings.

The conformity of PLATIT PVD coatings is certified according to DIN 1071-2, VDI 3198. Metal Estalki’s quality management system has also complied with ISO 9001 for more than six years.

Excellent surface quality of the coating. Roughness Ra after coating from 0.04 microns to a maximum of 0.15 microns, with the possibility of being reduced after a quick surface polishing. Typical CVD coatings are characterized by a much higher roughness which requires in all cases a costly polishing process.

Fast service

Shorter coating time than usual with CVD coatings, faster preparation and shorter coating cycles.

Environmentally friendly

The PVD coating process is totally environmentally friendly and safe because it uses compounds and gases that are safe for people and other living beings. In contrast, CVD processes must use gases that are extremely hazardous to human health and the process produces toxic residues which, if not properly treated, pose an environmental hazard.

Far from what it may seem, a correct PVD coating includes, in addition to the coating cycle itself, other processes of great importance. Metal Estalki is committed to a comprehensive service, so that all of them are carried out within the plant itself, without the need for subcontracting, which lengthens the time and reduces reliability.

Knowledge of the tool, the application and the processes is essential when determining the needs of each specific part or tool, which is why the advice of an experienced technician is necessary. Generically, the possible stages are as follows: