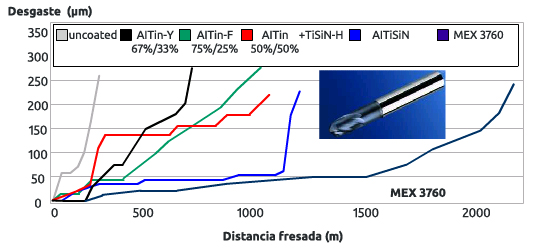

Areas of innovation / Projects / Machining of aeronautical materials

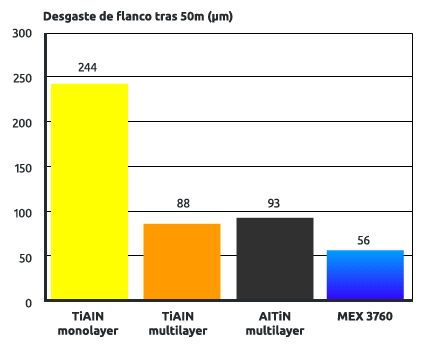

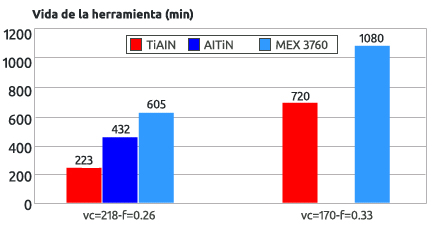

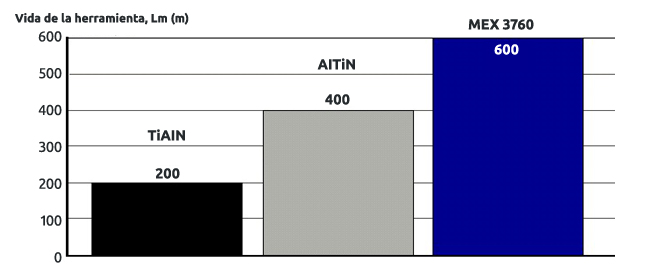

Steel machining

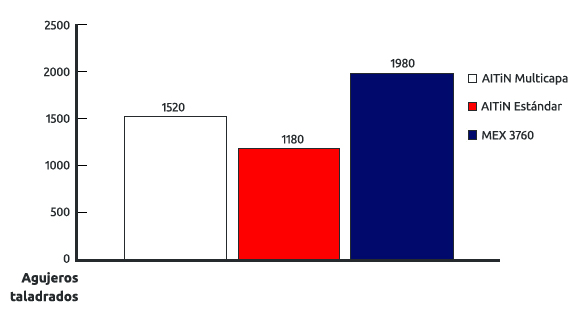

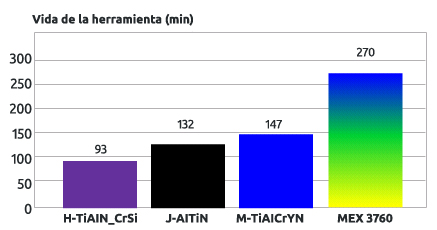

Milling of hardened steels

Tool

Steel X40CrMoV5 - 1.2344 - Rm = 1100 N/mm2

Material

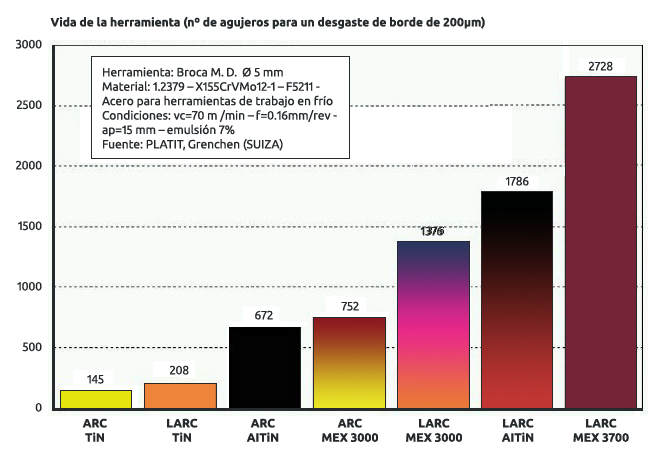

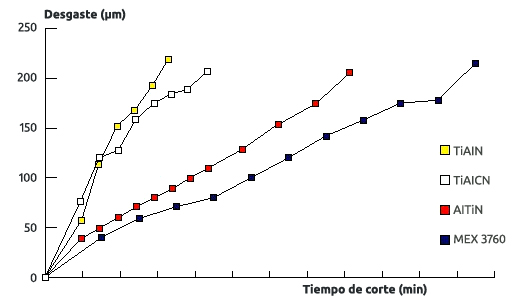

Steel 1.2311

Conditions

ap=0.5 mm - ae = 8 mm- emulsion 7 %.

Source

PLATIT, Grenchen (SWITZERLAND)