Injection molding processes cause abrasive, adhesive and erosive wear on the molds.

PVD coatings are the best way to protect and extend service life, protecting the substrate by providing hot hardness, thermal stability, wear and corrosion resistance.

In Metal Estalki we not only apply a quality coating, but we also enhance it by adapting it to the productive needs of the user, accompanying it with the following solutions:

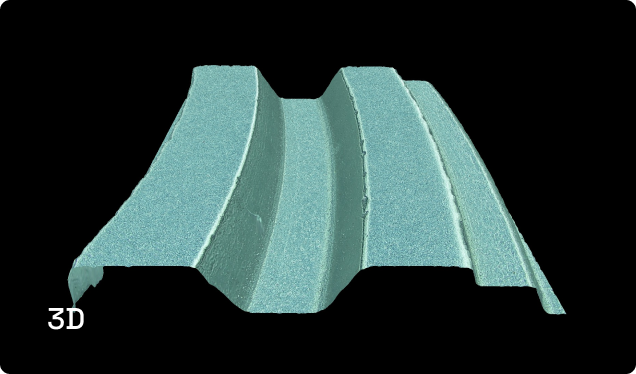

Duplex Process

Increases the resistance of the substrate against thermal fatigue.

Characterization of manufacturing quality

Surface preparation service

Tool surface optimization service, improving the tribological properties, reducing friction and respecting the surface textures indicated by the customer.

Plastic injection molding processes cause corrosive and abrasive wear on the molds.

PVD coatings protect the substrate by improving tribological properties and providing high wear resistance.

At Metal Estalki we are aware of the need to improve production performance, therefore we offer specific solutions that protect the surface quality of the molds.

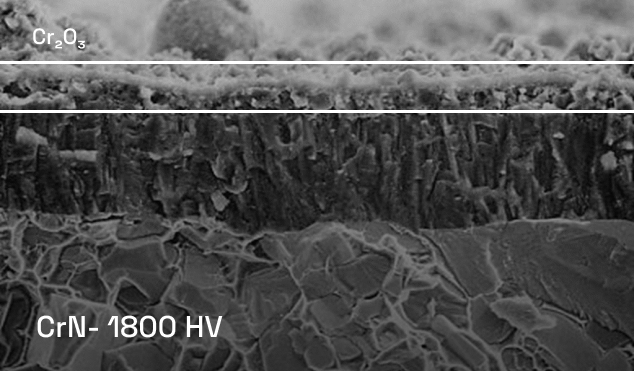

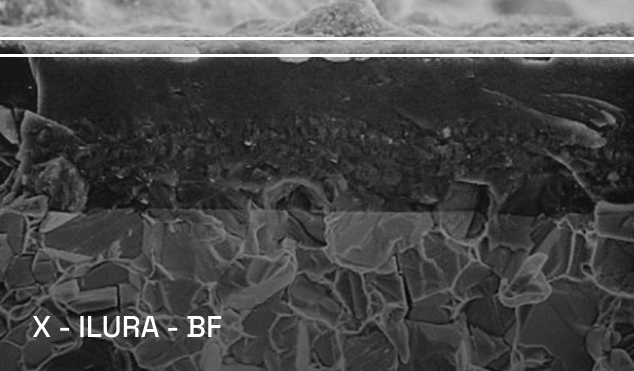

Coating with columnar structure

Unsatisfactory for multiple advanced engineering applications.

Thick and dense Cr2O3 coating

+ High corrosion protection (Diesel effects)

– Low hardness level (H) (~1100Hv)

– Low abrasive resistance

Porous and unprotected oxide

+ Higher degree of hardness

– Open porosities: Direct pathways between the corrosive environment and the substrate

– Rapid and localized galvanic attack of steel

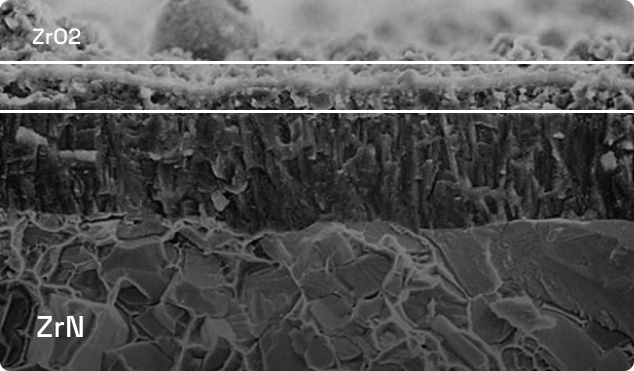

Specific solutions with both abrasive and corrosive resistance

They protect the substrate textures increasing the productive life of the molds.

+ Corrosion resistance ≥ CrN

+ H ZrO2 (~1800Hv) > H Cr2O3 (~1100Hv)

+ Nanocomposite structure: No diffusion of oxygen from grain boundaries

+ Nanocomposite structure: Increased resistance to oxidation and corrosion

+ Extreme hardness~ 4200 Hv